During a recent sewer maintenance project our client discovered a large void under the floor of the plant where leaks from the sewer line had eroded away the surrounding earth. Pearl Engineering was contacted and asked to help determine how large the cavity under the plant floor really was and to develop an action plan for repair.

Gathering a strong team of Geotechnical Engineers and High Definition Laser Scanning Experts to supplement his Structural Engineering expertise, Shane Burkart, PE set about analyzing the site conditions in order to craft a repair strategy. Burkart had previously employed High Definition Laser Scanning on other traditional projects but knew the technology could be inverted to help determine the volume and extents of the void with minimal access points and without hazardous confined space entry. Without the use of this technology it would have been necessary to lower a person into the hole to attempt to take measurements to assess the hole’s size and the scope of the damage to the surrounding ground.

During the investigation multiple 12” diameter holes were drilled into the cavity and scans were taken in order to get an accurate measurement of its size and shape. These individual scans were reviewed in near real time to strategically map out and determine the location for the next access hole core that would yield the best additional information. The entire data collection and investigation phase was accomplished with minimal intrusion into the facility’s operations and without further compromising the plant floor infrastructure.

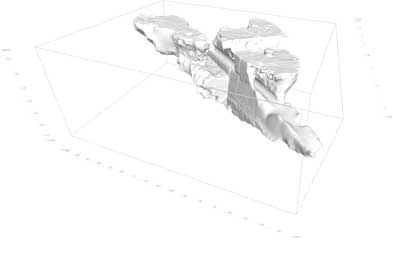

Once the individual scans were processed and compiled together the void volume was converted to a 3D mesh solid to determine the volume of the void and aid with repair plans. Lead by Burkart, repair plans are currently being developed in conjunction with the Geotechnical Experts and a specialty Foundation Contractor.

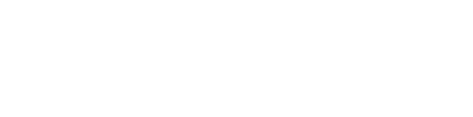

Figure 1: View of void showing missing sewer basin bricks and exposed pipe.

Figure 2: Isometric view of meshed 3D solid model of the void.

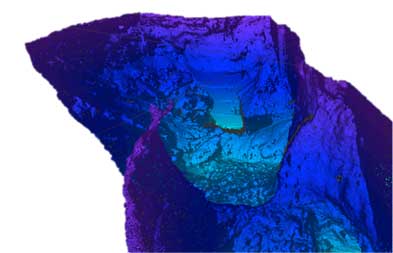

Figure 3: View of exposed sewer basin and building column foundation.