If you thought piping doesn’t require maintenance, think again. Many people are quick to notice and repair a leak, but few may take any notice of a broken or damaged support. In an engineered piping system, a bad support can cause unplanned stresses and, if unaddressed, may lead to catastrophic failure.

Support Types

Piping is a living component of your system. It moves, expands, and contracts. All of this movement needs to be appropriately controlled. There are a variety of supports used to perform this task, each with a specific function. For example, an anchor is used to fix a section of piping so that it cannot move or transfer forces to adjacent piping sections, while a guide is used to allow for movement in the axial direction, while limiting horizontal and/or vertical movement. Variable and constant supports are also used to actively support the pipe’s deadweight, while allowing vertical movement due to expansion or contraction.

Occasional Loadings

Changes in fluid or ambient temperatures, system cycles, fluid transients such as waterhammer, equipment vibrations, wind, and seismic activity can all cause active stresses in your piping system. In an engineered piping system, each of these loading cases is analyzed, and supports are carefully selected to mitigate the resulting stresses under all plausible operating conditions. Support selection and design is a delicate, and well thought out procedure. A single deviation from the design may throw the system out of balance and initiate the countdown to failure.

Thermal Stress Example

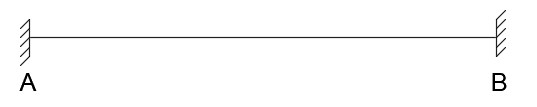

Consider a length of metallic pipe which is fixed with anchors on each end. An increase in fluid temperature causes the pipe to expand. However, in this case, the pipe is unable to do so, resulting in an increased force on the anchors and the increase in stresses within the pipe. If the temperature of the fluid continues to increase, the stresses will eventually overwhelm and damage the pipe, or the force on the anchors will cause one of them to fail.

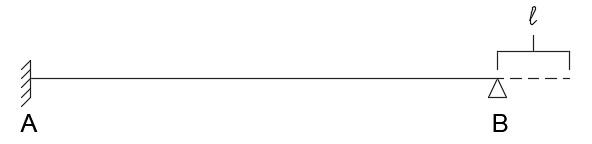

Consider the same scenario, but with the anchor at point B replaced with a guide. Now, the pipe can expand length l without risking damage to the pipe or the anchor at point A.

This simple example demonstrates how one support change can affect the entire system, and considers just one of the many occasional loading scenarios which was analyzed in the design of your piping system.

Notice a broken or damaged support? Give us a call. We would be happy to discuss your next steps toward resolving the underlying issue.